-

Posts

2,528 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Events

Store

Articles

Media Demo

Everything posted by Headsex

-

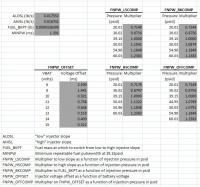

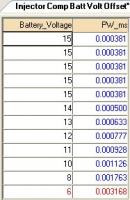

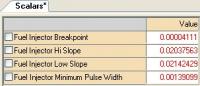

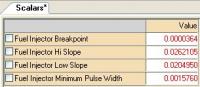

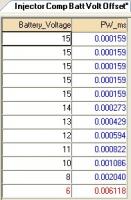

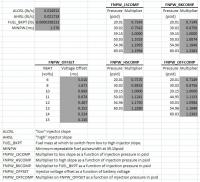

Here's the 80lb Siemens spec sheet from Ford Racing USA Scalars, breakpoint, and Min Pulsewidth Battery offset table

-

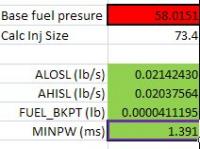

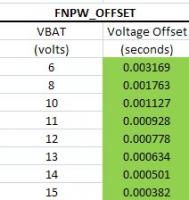

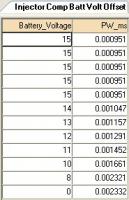

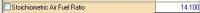

Some of you may remember the "great injector debate" of Siemens 60lb Deka vs Bosch 968's, and how many tuners liked 968's over deka's. Infact, some HATED deka's!!!! The discussion then turned into a mess regarding drilled injectors, and spray patterns etc. Please don’t turn this thread into that. One particular workshop mentioned the reason why they hated Deka's. The main reason being the LOW injector slope is so "fat" in comparison to High injector slope, causing an unwanted rich idle/midrange until the pcm switches over to the high slope Let me Illustrate. Factory Injector scalars High Slope 0.00929140 Low Slope 0.01357369 Example of 968 scalars High slope 0.0124620 Low Slope 0.0199999 Now with 60lb Deka Injectors, I've seen values like this. High slope anywhere from 0.0180 to 0.0210 Low slope anywhere from 0.0270 to 0.0370 Personally, I have used 0.0190 for the high slope, and 0.0325 for the low slope, and allowed adaptive fuel control clean it up. But this is WRONG I can guarantee that anyone who’s scaled 60lb injectors would be doing something along those lines. If you multiply the scalar by 3600, it will give you the flow in lb/hr. So 0.038 * 3600 gives 136lb.... So as its been mentioned previously, The Siemens injector thinks it’s a 136lb injector at idle pulse width sizes. Now in the past, I've offered my assistance to a few interstate tuners with scalars for the dekas because they swear deka's are crap, have problems, etc. Which given the way they are scaled, they do have valid points, especially since having real poor fat idle (before adaptive fuel control cleans it up somewhat, But not completely). But there is something FUNDERMENTIALLY FLAWED in how Australian tuners are "scaling injectors" for our cars. Back at the start, People started altering High slope, and Low slope values for Bosch 968 injectors. Sure, sounds easy to do, just keep adjusting the numbers until fuelling is right. And you will come very close to those scalars I mentioned before. And they perform perfectly as the factory ones did. Now, do the same approach with a Siemens Deka Injector. And you end up with the above numbers, crap idle, which most fix by raising the idle speed etc. Why? Think about it for a second. 968 injectors are Bosch injectors. Deka's are Siemens injectors. The Bosch 968 injector is mechanically the same as the original XR6 Turbo injector as they are both Bosch, just with differently calibrated metering holes. Oh, for those thinking of Drilled injectors. This also stands correct; they are still mechanically the same. Deka's are not the same mechanically as a Bosch (duh). Have a look at the following Image. Wow... What do we have here? Spec sheet for a Siemens injector AS RELEASED by Ford Racing USA! Surely if the siemens injector were bad, why would Ford Racing be using them, or even releasing spec sheets for us tuners. The high and low injector scalars look fairly close to one another... That’s a bit different from what I showed previously... But why? Sure, those scalars are for 39.15psi (just below 3bar) base fuel pressure, not 4bar as XR6 Turbos run. But using the FNPW_xxCOMP multiplier tables, we can easily work out new injector scalars using interpolation value of 58.0151psi (4bar) using the LSCOMP/BKCOMP/HSCOMP tables giving us the following scalars Go put that into your Tune, and Wait a second, it still running like crap, Air fuel ratios are wrong. Etc. What else do you see on that original spec sheet? "FNPW_OFFSET" This is the amount of "Opening time" in ms the PCM commands prior to fuel coming out of the injector (vs. battery voltage). Obviously this is based on 39.15psi (just below 3bar), so based on the FNPW_OFFCOMP table, interpolation 58.0151psi (4bar) from the table gives us 1.22374 multiplier, giving us the following "FNPW_OFFSET" table. Now compare this with the Factory Battery offset table (which was setup for the Bosch injectors @ 4bar) Original Bosch first, and calculated Deka's last What do you notice? The deka Injector DOES NOT need as much Opening time at 12volts as the Bosch injector does. ie, at 12 volts, the Deka injector only needs 0.777ms Opening time compared to the Bosch of 1.291ms Doesn’t this tell you the Bosch injector is slower reacting than the Deka injector? What do you think is going to happen if you leave the BOSCH battery compensation Offset table with increased opening times when using Deka injectors? Whats this going to do in fuel metering? Its going to add extra fuel that the PCM doesnt know about, and hence, people come up with strange Low slope scalers.. Hey I admit, I did at the start. Can you understand now why the way people scale NON BOSCH injectors is FLAWED? Its because they are ignoring the Battery Volt Offset compensation table! If your a DEKA NON BELIEVER, I put it to you to try these These Injector values completely, High slope, low slope, break point, MIN PULSE WIDTH, and addjust the Battery Offset table and then decide what you really think of 60lb Deka's Please note, Regarding the High slope value, You may need to alter this slightly depending if the existing fuel system is upto it.. ie, intank original, walbro, or a bosch 044. I also have the 80lb Siemens spec sheet, Once I finalise my install, I will post details for them also.. 80lb injectors give us the ability to run E85 as it needs 40-50% more fuel flow than normal Petrol. Tuning for E85 from a fueling point of view is easy, you just have to tell the PCM that lambda 1 of the fuel being used is 9.85.. Or if you run 10% ethanol fuel, a value of 14.1 will make sure fueling is correct and commanding the same lambda as per your base fuel table. Located under "Fuel" Scalars Here's the Spec sheet for the 80lb injectors from Ford Racing USA Scalar values calculated from the interpolation of 58psi Battery offset calculated from the interpolation of 58psi Notice at 12volts on the Battery offset table, they have a quicker opening time than the 60lb injectors, as well as the Low slope being smaller than the 60lb injectors.. Im starting to think there will be NO idle problems with these injectors..

-

Well Im currently testing the servo, Phils getting a number of them CNC'd, as this one took 6 hours to make manually in a lathe. Going to test a handfull of them in various cars phil has picked to see any longevity issues.. And well, yeah, it is alot of power im pushing, but a number of people have done it the trick is to have no traction, and it doesnt load up the rods =).. haha kidding!

-

With my old stall convertor (it was very tight, similar to factory, but with better driver), it showed 398.6rwkw. After changing my convertor, without touching the tune, it dropped to 370rwkw.. convertor has more stall, but its still got good positive drive in it. Bottom end is holding up well..... I do have a major oil leak from the front of the balance seal I believe.. need to investigate it further..

-

I've calculated approx 600rwkw. But your results may vary =) plans are? GT42R on the standard bottom end for now.. and push the power up more.. Phil @ bayswater has just developed a aftermarket servo for the 4 speed box.. Yarra valley have been using this for some time in some of their "HIPO" boxes.. So its definately given me more comfort in the 4speed holding up. Lets see how far we can go.. My next goal is a 9 second pass.. Not saying its going to happen in this current setup, but that's the next goal.

-

Old news.. keeping it now =) unless you offer me silly money for it

-

definately.. Especially since the turbos already on the car

-

What? like this one?? notice the blocks removed adam? Just awaiting roger ramjet to come polish it for me

-

Sure will.. might do this tomorrow infact

-

Nope. High Impedance.. Different plug type, EV6 instead of EV1, wiring adaptors required Give me a few hours and they will be in.. And no, siemens 60lb injectors are more then enough for the power a std turbo can produce

-

-

that's right 83lbs 850cc

-

Very close =)

-

Well, Some time ago, I bought 60lb Siemens group buys to the forum to benefit members. where 60lb injectors found their way into many vehicles to date, Giving upto approx 430rwkw in fuel supply. But as if anything, People who chase the bigger power need more.. Now 10 points to the person who guesses what injector this is =)

-

siemens are good value for money, alot of workshops have no problems tuning them.

-

That is what I ment..

-

that's right, I believe with the VCM/HPTuners, and even Sniper stuff, Once the appropriate credits/bullets are purchased by your Dealer for your car(VIN number), Any tune updates afterwards dont cost any more credits/bullets if you go back to the same tuner. If you goto another tuner, you WILL have to purchase more credits/bullets for them to license your vehicle on their device. If you had a SCT box, you just take your box to your nearest SCT tuner.. Pro's and Cons about both methods

-

That goes with ANY workshop.. Some workshops send your car out after 3 runs on the dyno with a rough/crap tune, and some "spend the time" and do over 10 pulls on the dyno to perfect the tune, and sometimes go the extra mile and road test it also, Bringing out any drivability problems you cant diagnose on the dyno. However, this has lead off topic of the original post.

-

A Dyno graph comparison on a car tuned by 2 different tuners isnt a way of comparing software. As Ratter has mentioned previous, All these tools, Be it, SCT, Sniper, or VCM, Only provide access to Tables within the PCM, nothing more, nothing less. Some software is easier to use, ie, VCM is very nicely presented, compared to Sniper, which will have you scrolling for months looking for that table. You mention that boost control seems to hold 11psi, instead of 9psi, which can be influenced by manythings. Now, Since you didnt do the "SCT" tune, I can almost garentee your tuning techniques on a Turbo would be different to the workshop that tuned this vehicle previously. Running a XR6 Turbo with a standard actuator will see anything from 9psi to 11psi up top, and even as high as 18psi running 100% wastegate duty cycle, the exhaust and intake setup make a huge different here, BUT, Since you done a back to back dyno run, It would indicate that the intake or exhaust was not changed, Only the tune was. From a tuning perspective, as you know, changing AFR plays a affect in the amount of boost it can hold, as well as the amount of Spark being delivered asssuming the previous tune was running 100% wastegate duty I just dont believe people should be Mislead to thinking that "X" Software instead of "Y" software was the contributing factor in why this car made more power compared to before. But in saying that, If one software is easier to use over another piece of software, and helps a workshop tune more effectively, then so be it. But this is not the case here. Also, About the live tuning. Ford have dev pcms, which contain a device called a "M6" under the main microprocessor within the PCM itself. This device is basically a Memory Emulator. Its not flash memory (which is what your pcm contain now), but rather, RAM, which looses data when power is lost. But also changable without having to Erase the entire chip, or Banks of the chip prior to making a change. Here is the link to the device. http://www.accuratetechnologies.com/en/pro...rs-257-254.html Combined with the appropriate software also produced by Accurate Technologies, "VISION", Allows Real time changes, as well as Real time monitoring, Must faster than you can suck out of a OBD port using PIDS, OR DMR requests. http://www.accuratetechnologies.com/en/pro...re-178-174.html Have a look at the screeen shot there. Because our PCMs have Flash memory build into them, before any change can me bad to a spark table for instance, requires either a FULL erase of the chip, or a Sector erase, erasing a large block of the Flash Memory. For obvious reasons, your unable to do this live whilst the PCM is running the engine. Further to this, Erasing flash memory, be it entire, or partial, can only be done via the Ford designed bootloader, Which is why when using a SCT box, you have to start the program process prior to turning your ignition on. The technical reason behind this is the SCT Flash box (or VCM, or Sniper) applies 18 volts to pin 13, known as the FEPS line. On Ignition sequence, the Processor looks for this, and switched to a bootloader mode if its detected. In the past, older pcms required 18 volts applied as old Flash memory needed a 18volt source for erasing.

-

outrage worked? 90 days isnt a perminate solution... I can see alot of flash boxes hitting ebay

-

feel free to update this forum on his post for those who dont visit the other forum

-

They say precautions were taken with xcal3... But could you trust them with a manouver like this that has been pulled?

-

yep.. here is the direct link to it.. http://www.sctflash.com/software/LiveLink441.exe

-

download the livelink software off the sct website.. it makes a good datalogger =)

-

Actually.. No... Simple terms.. I still have 280 flashes left before I'm forced to update... Im sure ALOT of workshops havent updated yet.... Call up your tuner and tell him to disable autoupdate if they already havent updated...