-

Posts

2,528 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Events

Store

Articles

Media Demo

Everything posted by Headsex

-

Yeah, like tomorrow:) And no. not for Tuning purposes Infact, I'm not sure what im doing either night, will know more when im in sydney in the morning..

-

Hey guys, Going to Sydney for a few days for work. In the North Ryde/MacQuarie Park area Let us know if your nearby and up for a drink either Tues/Wed night..

-

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

Well, how do you know your getting yuor injector high and low slopes correct if yuor not datalogging what the PCM is doing. STFT = Short term fuel trim LTFT = Long term fuel trim. Immediately by datalogging these values, you can see WHAT the pcm is doing when in closed fuel control. Ie, You start your car, and after 30 seconds, when the PCM switches to closed loop, You will notice these numbers start the move. Ideally you should see STFT bounce between 0.97 and 1.03 in like a Triangle Wave shape (I will put some datalog screenshots up tonight) This indicates that your fueling is correct. your LTFT will give you a idea on how far your low slope injector values are out. This is a slow moving trim, so yuo must sit at idle (no accelleration) for at least 1 - 3 minutes for it to stablise. Ideally this value should be close to 1.00 as possible. If you see 1.10 for example, your approx 10% too lean, because LTFT is adding more fuel (STFT opperates in reverse, but ignore STFT for now). If you see 0.90 on LTFT your injector low slope is approx 10% too rich, and the LTFT is pulling out fuel. Forget for 1 moment about your AFR meter in yoru exhaust, Use LTFT/STFT to get your Injector Low slope correct. the AFR meter is only really good for checking yuor High slopes, as when your Wide open throttle, the pcm is not opperating in closed loop, so STFT and LTFT become inactive! Yes well I wouldnt be going wide open if the AFR's are not lower than 12.5afr with 15psi boost..... Idle and Cruise and all light throttle are all lambda 1. Have a loop at the "Open-closed TP" table, which shows you what TP count makes the PCm go from Closed loop to Open loop. All Closed loop is targeting 1.0 lambda! My guess is your wastegate port is not done. Hense why boost will be uncontrollably above 15psi.. IF yuo cannot get boost down to the level of your actuator spring, then your overboosting. Some tuners will tune the car in its current state, but personally I can't get the level of boost control I want, so I won't do it. Fact is, at night when air temps drop even more, the Boost will rise higher! -

No, I just remembered it "I have a headsextuned sticker, why dont you?"

-

haha what was that old one that I told you I loved?? I think it was your first one...

-

Basic physics. It's fact not theory

-

the pressure difference occurs at the most restrictive point, ie, the metering disk. So there's 1bar boost on one side of the disk, and 5bar fuel pressure on the otherside of the disk.

-

Your forget that there is also 24psi in the manifold, providing a resistive opposing pressure on the outlet side of the injector. So the pressure differential is Fuel Rail pressure minus manifold pressure.. Ie, 4 bar!

-

Not to sound rude, but yes, your missing it. Lets go back to basics. Take these 80lb injectors. If you have a naturally aspirated car, running 2.7bar(39.16psi) fuel pressure. The injectors will flow 75lb If you wind the fuel pressure upto 3.5bar(50.7psi). The injectors will flow 85lbs If you wind the fuel pressure upto 4bar(58psi). The injectors will flow 90lbs Now remember one thing...... Your Naturally aspirated. So at wide open throttle, there is 1 Atmosphere pressure(absolute) in the engine (ie, What we all breath right now) or better yet, 0 Atmosphere pressure(relative).. ie, THERE IS NO BOOST. Now lets take a boosted car for example. The purpose of the fuel reg is to Rise fuel pressure when the pressure inside the manifold raises. Ie, when your making boost. MOST Regulators have a 1 to 1 relationship. So every PSI boost increase, will have the same PSI increase in fuel pressure. SO.. Example.. Once again, If you are running 2.7bar(39.16psi) fuel pressure. The injectors will flow 75lb If you have 15psi, your fuel pressure is going to be 15psi HIGHER than what it was at 0psi. So, you have approx 54psi (3.7 bar). But The injectors will still flow 75lb. Although you have HIGHER fuel pressure. You now have 15psi resistive pressure on the outlet side of the injectors. Taking our 4bar base fuel pressure, the injectors flow 90lb Base, with NO boost Add 15psi boost to it (approx 1 bar), then you have 5bar fuel pressure, But you also have 1bar boost pressure on the outlet of the injector. So the increase in fuel pressure is negated by the boost in the manifold. Hence the injector STILL SEE"S 4 bar fuel pressure.

-

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

0.001 is max limit In advantage also, but you can disable Min/Max checking values in the options to override this. And yes, I'm 100% confident Minimum pulse width on the 60lb injectors is 1.391ms (0.001391), its just that your software is not allowing you to go past the min/max values. In saying that, I would assume your Spark load table is not changed away from 1.4 as your maximum also. Do you use a datalogger to check STFT and LTFT's ? Ideally you want your low slope correct so that your STFT and LTFT are hovering around the 1.00 mark. STFT will have a wave to it, but LTFT should be close to 1.00 Dont even LOOK at your Afr meter, It will only tell you approx 15 seconds if your too rich or too lean, at approx the 35 second mark, the PCM starts closed loop fuel control, and that's when you see your AFR go closer to 14.6. At this point, watch your LTFT on your datalogger.. If your LTFT shows 1.15, your 15% too lean, and its adding fuel, if its 0.75, its too rich, and removing fuel. -

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

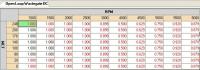

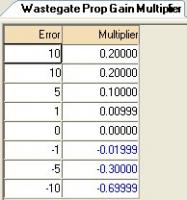

His on the ball.. The clicking is the solenoid running at like 0.3 duty cycle at 1000rpm. your obviously tuning in Open loop. Change the very low rpm duty table to 1. Attached is what my duty table looks like.. And my desired boost table.. As its operating in closed loop, My duty cycle varies depending on weather conditions, and 99% of the time between 4700 and redline, it sits at .99 duty As it had trouble targeting higher than 17.5psi anyways. On a extreme cold night, I'd be lucky to get 18psi as my actuator is simply just run out of spring. Technically my Desired boost table from 4500rpm onwards should be 36. And because I'm feeling generious.. Here's my Wastegate Prop Gain multiplier table... 99% of tuners Zero this table out, eliminating closed loop and forcing open loop. You know what? I was going to keep them a secret. But f*ck IT. This will puzzle ALOT of tuners.. Notice all the integrals and proportional gains are still set to factory?? As if I'm going to redesign the PI loop that ford spent many man hours doing. Notice my P1227 Level is NOT disabled (this is your overboost protection).. Most tuners set this to 255 essentially disabling your overboost protection. and "Wastegate boost FMEM" is the amount of engine reduction WHEN you hit overboost.. Once again, its left as standard. There is no f*cking secret to closed loop. The Secret is KNOWING how to setup the Desired boost and Duty cycle table to work correctly together! -

haha yeah.. I just noticed his signature.. Hayden, Put it below the pic, not above it.. I think him and Rspec got together and started playing signature wars!

-

Yep! sms me he has 330rwkw LOL. Who cares what power it has.. it kicks arse on the street. that's all you gotta care about!

-

60lb injectors run out at about 450rwkw. maybe less, depending on your commanded air fuel ratio! Sure, The injectors will flow more at higher fuel pressure, But your theory only works in a Naturally Aspirated vehicle. Adding 25psi of boost, and rising the fuel pressure to around 6bar still has a 4bar pressure differential over the injectors feed and tip. Therefore the injector still see's 4bar pressure.

-

that's right!! So next time your around here, we need to alter your injector values to suit :D

-

These injectors are now Happily running in my car at lambda 1 at FACTORY IDLE rpm.. that's right, approx 600rpm in gear. or 750rpm in netural. See below for more details. As Mick has pointed out, Ford Racing have Re-released the injector values. I Emailed them regarding the problem I had, where the pcm was idling on the Minimum pulsewidth causing a excessively rich problem as the minimum pulsewidth was too much fuel. I told them I experimented with Lowering the Minimum pulse width, but cranking up the Battery offset table because the PCM shuts down the injectors if the calculated fuel pulsewidth is LESS THAN the "minimum pulsewidth" remembering that if the injector doesnt have enough pre-open time, It may fail to open anyways, So the injector needs at least 2ms opening time I've been told. But the problem is, the PCM's equation does not include the Battery Offset ms opening time in the calculation for minimum pulse width. They told me they were already well aware of the problem and were in the process of re-releasing the spec sheet with the new finalized results. Obviously Mick saw them before I did. So if you compare the original and revised specs, you will see that, the min pulse width was set to 1.57ms, and now a revised 0.599ms. BUT in the Battery offset table, the pre-open time at 12volts was originally 0.595ms, and now a revised 1.25ms. So, If you look at this following v2 Specs from ford Racing Here is the calculated details @ 4bar base (58psi) All important Advantage 3 Screen shots

-

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

Just out of interest.. Try these numbers, This is one of the extreme's I've set where idle was lean with 60's.. Break point 0.0000411 Hi Slope 0.0185 Low Slope 0.0183177 Min pulse width factory setting of 0.0003499 obviously update the Battery Volt Offset as per my screenshots above for the 60lbs. Now keep in mind. the PCM does NOT idle at Stoich lambda 1 (14.64 AFR), Looking at the o2 offset table, its idles at .9% richer.. ie, 14.50 is what it targets.. Now if you run 10% ethanol fuel, that then changes to stoich from 14.64 to 14.08 (you should put that number into the fuel scaler for lambda stoich), and with the .9% bias, the Idle should be around 13.95afr -

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

Here is the updated 80lb injector Spec sheet.. Look at the major differences from the original. Here are the scalers as computed for our fuel presure of 4bar base (58psi) The all important screenshots from Advantage Injector Scalers Injector Comp Batt Volt Offset -

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

Ahh ok. I must have missed that part. Either way, Both the high slope and low slope need upto say 10% adjustment either way to suit the vehicle, even though these values are "engineeringly correct", Other fuel system problems may be lurking there.. In your case, I’d check fuel reg. put a fuel pressure gauge into the feed line. Other possibilities for a big change in high slope values could be insufficient pump, either being volume, or pressure. Remember that the xr6 turbo runs a higher than normal 4bar base fuel pressure. With 15psi, that’s 5 bar of fuel pressure as the fuel pressure raises with boost. You have to make sure that your fuel system, in particular, fuel pump, is rated at 5bar or higher. I recently tuned a particular car with a GT42R turbo, which had a single Bosch 044 pump mounted off a surge tank. I noticed at 15psi, afr's were perfectly flat, with the commanded lambda, indicating that the speed density tables, and injector slopes were correct. Raising the boost to approx 20-21psi, resulted in correct midrange afr's, but as the RPM reached 5000rpm, the AFR's rapidly started leaning out to the likes of 0.86 prior to backing off. Changing the high injector slope as a test resulted in extremely fat midrange afr's, but the same lean off above 5000rpm. This was indicative of insufficient fuel pump pressure. Which was later proved when a fuel gauge was installed, fuel pressure was dropping when it should have remained stable to boost at the higher rpm. Doing the math behind it, 4bar base, plus 21psi, comes to approx 80psi fuel pressure. A Single Bosch 044 fuel pump mounted off a surge tank does not have enough balls to run at this fuel pressure. Infact, a Bosch 044 is rated at 600hp in a forced induced setup. With nearly 400rwkw, it works out to be exceeding the pumps capabilities. That was just an example on where Injector scalers "look wrong" due to fuel system problems. Obviously your experience will vary... I hardly ever change speed density tables for these XR6 turbos. Ford got the calibration real good. I have however seen examples where people change the High rpm speed density values to cater for the ford running richer in higher rpm. But here's a brief explanation why this happens, and why changing the speed density tables is engineeringly incorrect. Remember what I said above about fuel pump not being adequate. Let’s take an example of a car. A XR6 turbo, with nothing but a good intercooler and set of injectors. Having a standard actuator will result in a typical boost curve coming in, and spiking at say 15psi, and tapering off down to 9psi high in the RPM. Think about what I said before about fuel pumps being able to flow more at lower pressures, or rather, running out of puff at higher fuel pressures. Boost coming in at 15psi would put a burden on the fuel pump given the fuel pressure is rising with boost, and then when boost comes back down to 9psi, relieving some of that burden on the pump and it pumps the fuel easier, its going to show say 12.2 afr's midrange, and 11.9 afr's top end. It’s a case like that where I’ve seen tuners adjust the higher rpm speed density tables, or even the speed density correction table, which I’ve seen people incorrectly use (but that’s a different story). Usually this is evident with standard fuel pumps, where the pressure relief valve is starting to spring open. In my vehicle, I have a 044 Bosch with a surge tank from process west. I run approx 16 to 17psi on united 100 fuel. as its coming up to end of pump if I push the boost up higher, my commanded afr's is flat, as my resulting afr out the tailpipe is nearly flat, it does slightly sway leaner high RPM, but that’s pump related, not incorrectly adjusted speed density tables. -

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

A few posts ago you mentioned you were running Nizpro injectors? These values are for Siemens Deka's. Did you change injectors? or is this another vehicle you are talking about? What commanded Lambda are you using to get a resulting 12.4afr ? -

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

Yes, I was informed about this, and noticed the major issue is because people like me were resting on RICH min pulsewidth for idle. This is mainly due to how the PCM internally computes the pulsewidth. It would seem it ignores the Battery offset opening time when checking against the min pulsewidth value. Changing the min pulsewidth from 1.5ms to 0.599ms, and bumping up the battery Voltage offset allows less fuel to be injected I will upload the new figures this evening. Its amazing what a little bit of feedback does.. Infact, they mentioned they already knew about the issue. Good to know Ford Racing stand behind their products. -

you have half a eyelet of pretension on that actuator. I think you just got a mislabeled 9psi actuator, this is why I dont like BYO products

-

Ok. a update on these 80lb injectors.. I do NOT recommend these injectors unless you NEED to make big power. The minimum pulse width of this injector is 1.58 milliseconds. Far too great for idle, unless you set your idle to 1100rpm.. In gear when the engines loaded up a bit, its happy at 800rpm at lambda 1. But when its in neutral/park, forget it, Rich idle.

-

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

Wouldnt say its the drilled injectors doing it.. Under "Accelerator Pump" Change the "Accelerator Pump Filter for Tip out" to 0.000000 -

Why Tuners Hate 60lb Siemens Deka's

Headsex replied to Headsex's topic in Fuel System & Induction Workshop

that decel hunting you so call can be address by disabling the Decel Tip-out.. setting it to 0 =) Also guys, this isnt a Drilled injectors vs Deka injectors. I just highlighted this fact that when shops scale injectors, they do not alter the Battery Offset table, which essentially is the open time. Deka's dont need as much "opening time" as Bosch injectors. This is why people say deka's suck because they have sh*t idles due to being so rich, or not having enough pcm resolution to adjust Previously, Setting up this table would have been impossible without the specification sheet from FORD Racing. But the value file that sct provided was "close" to whats required, albiet for only 39.5psi, not 4bar. So it still required modification to the slopes as well as the Offset battery comp table. Also keep in mind, the High slope and Low slope may need some alterations to suit your application. They are a GUIDE only. But it should be withing 10% of commanded AFR's. My car, since I am running united 100, has 10% ethanol. Being that, I have also altered the "Stoich AFR ratio for lambda 1" under the Fuel scalars to 14.1 instead of 14.64. My High slope scaler is also around the 0.0192 mark (not 0.0203). As it ran a little leaner than commanded AFR.